Global Sourcing

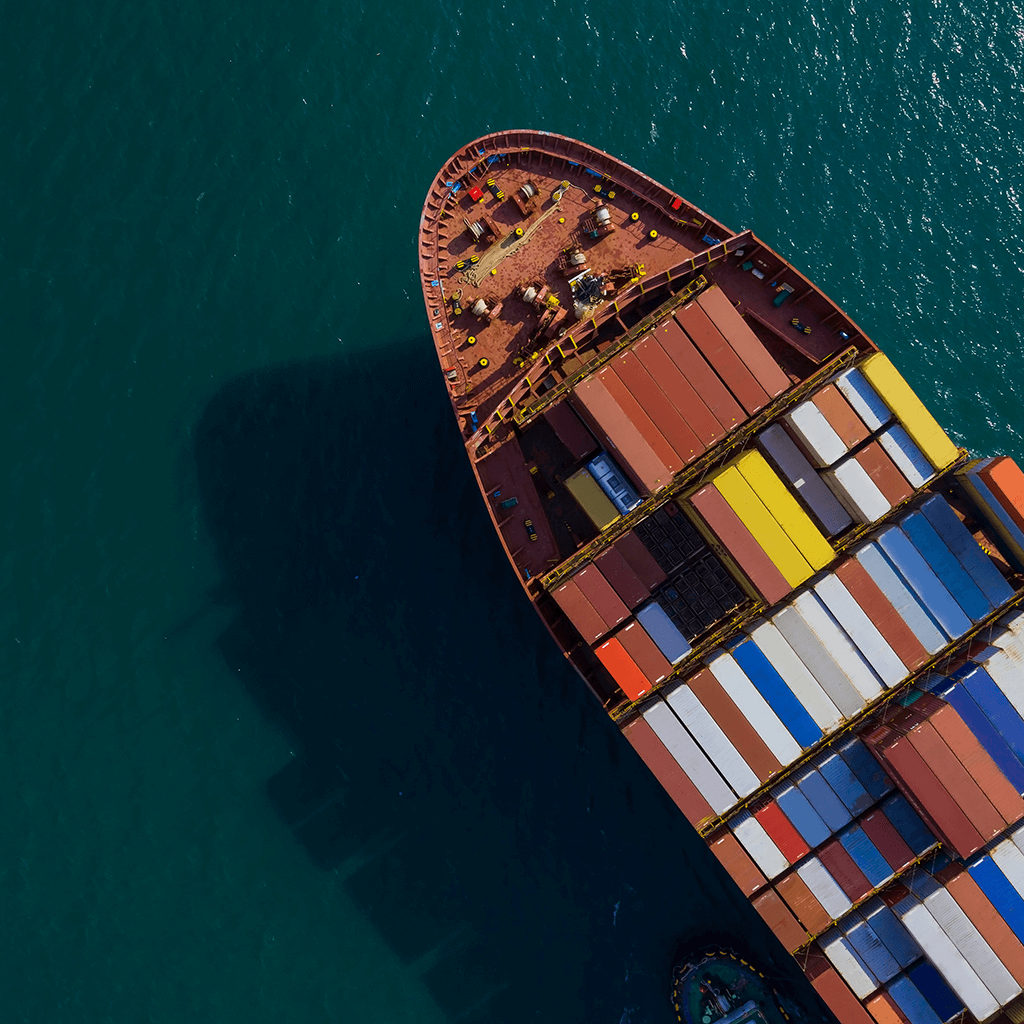

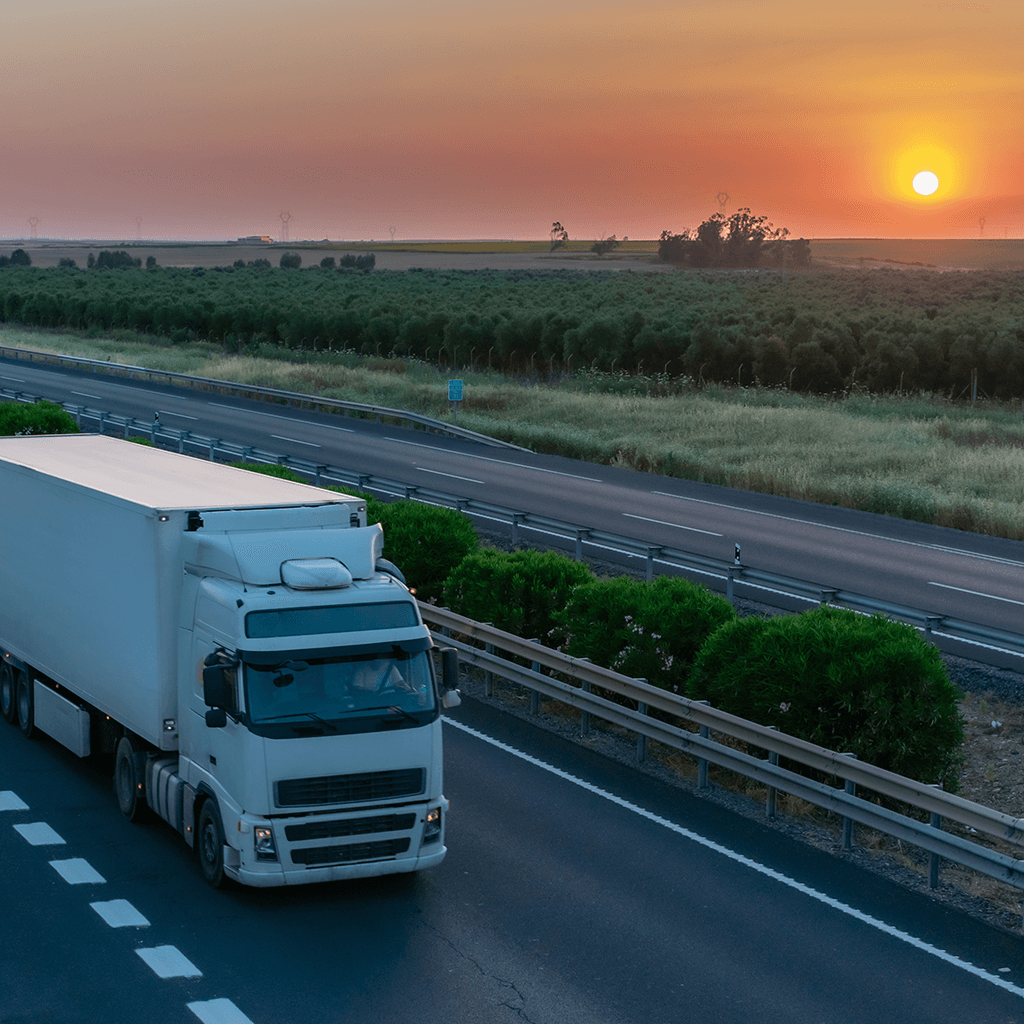

The optimisation of your global supply chain requires an EMS partner who has outstanding electronics supply chain management (SCM) and can bring your product to market efficiently. This means removing as much risk as possible by working with a leader who understands how to seamlessly integrate electronic components suppliers and speaks the language of engineers and international customs agents, so delivery avoids any import or export delays and is on time, every time.

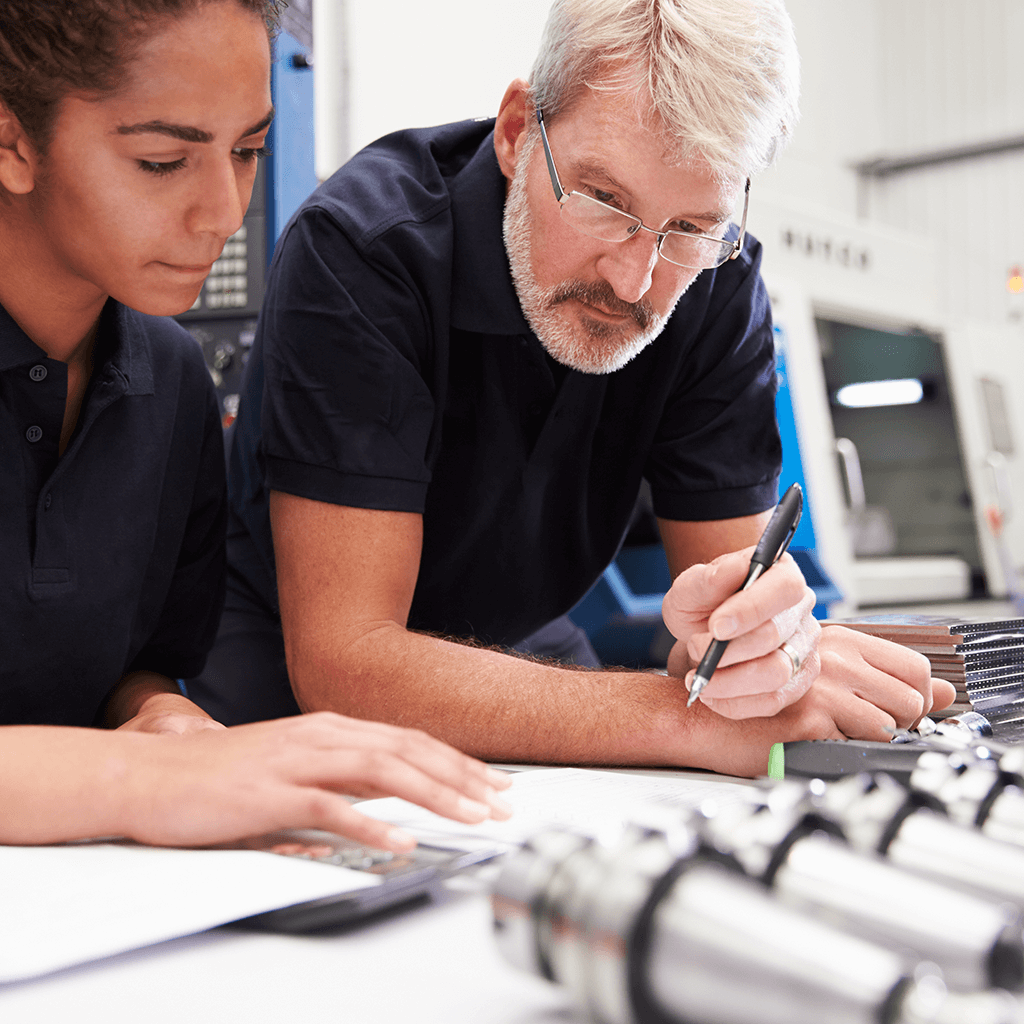

We understand the pressure that comes along with needing to meet customer commitments, and the stress of being resource-constrained. Evaluating outsourcing options begins with knowing your core competencies. Once you completely understand that aspect, you'll be able to partner with a provider that offers more expertise and experience in other areas, allowing you to focus on what you do best.

TT Electronics' secures millions of individual parts and components used in printed circuit board assemblies (PCBA), cable harnesses and complete integrations for our customers. From hard-to-find components to standardised parts, we identify options based on specific manufacturing needs.