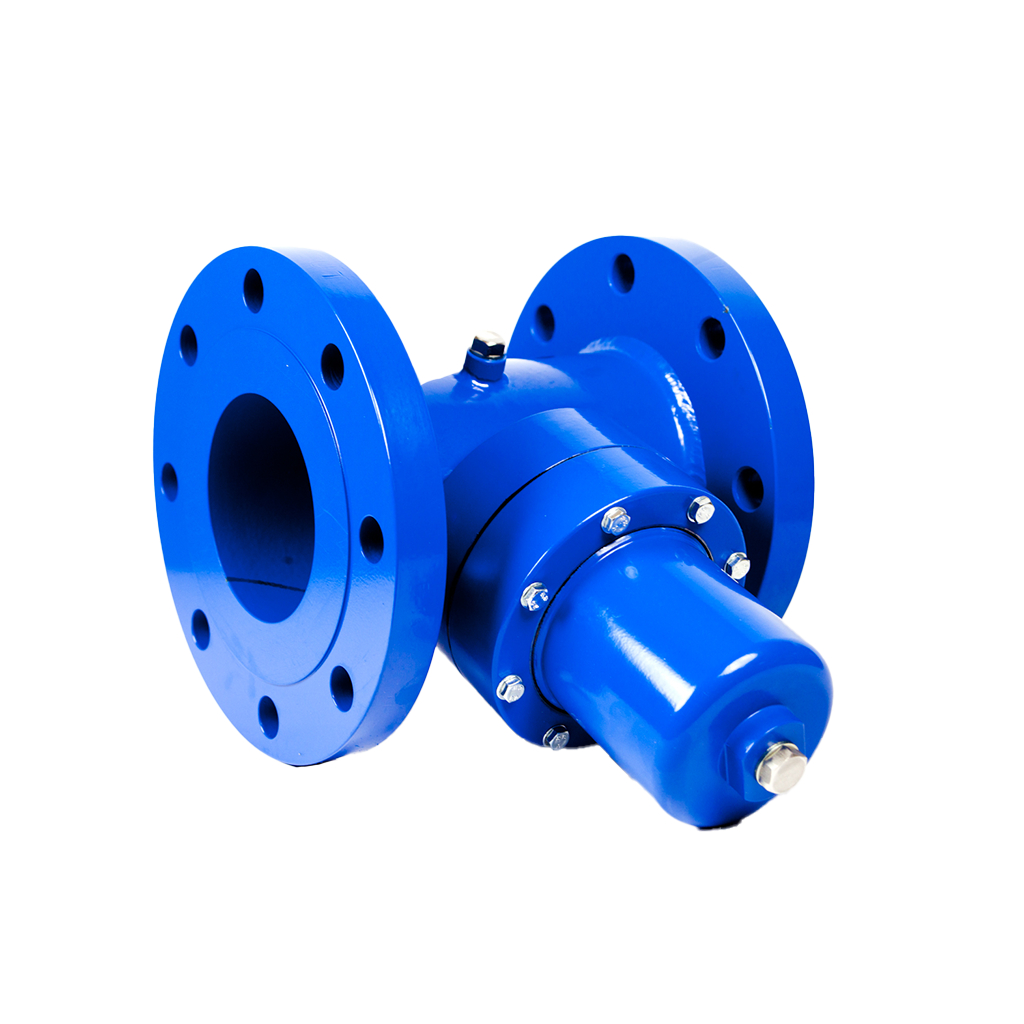

Flow Sensors

Flow Precision

UK’s premier manufacturer and supplier of flow measuring devices.

From individually calibrated anesthetic flowmeters, orifice plates, ultrasonic flow meters, to pressure and flow regulators, Roxspur Measurement and Control can supply all your flow measurement and control needs. Our flow measurement technologies include ‘variable area’, ultrasonic, magnetic, turbine, and laminar flow principles are all available, together with a wide array of controllers, displays, gauges, switches and regulators.

Explore Our Products