Modified Standard Power Supplies: The Best of Both Worlds

Your latest design is wrapping up, and it’s time to select a suitable power supply to ship with the product. A quick parametric search on your favourite electronic component distributor’s website yields a half dozen viable candidates, but none seem to incorporate 100% of the features you were looking for. Do you resign to change your DC input connector to get the cable length that product management wanted? Do you take a hit on the cost to ensure you have the headroom you wanted for peak power events? These power supplies were designed for general purposes, not for your purpose. The project can’t afford the delays, costs, or sourcing risk associated with a custom solution, so where do you concede? It may be time to consider a modified standard solution.

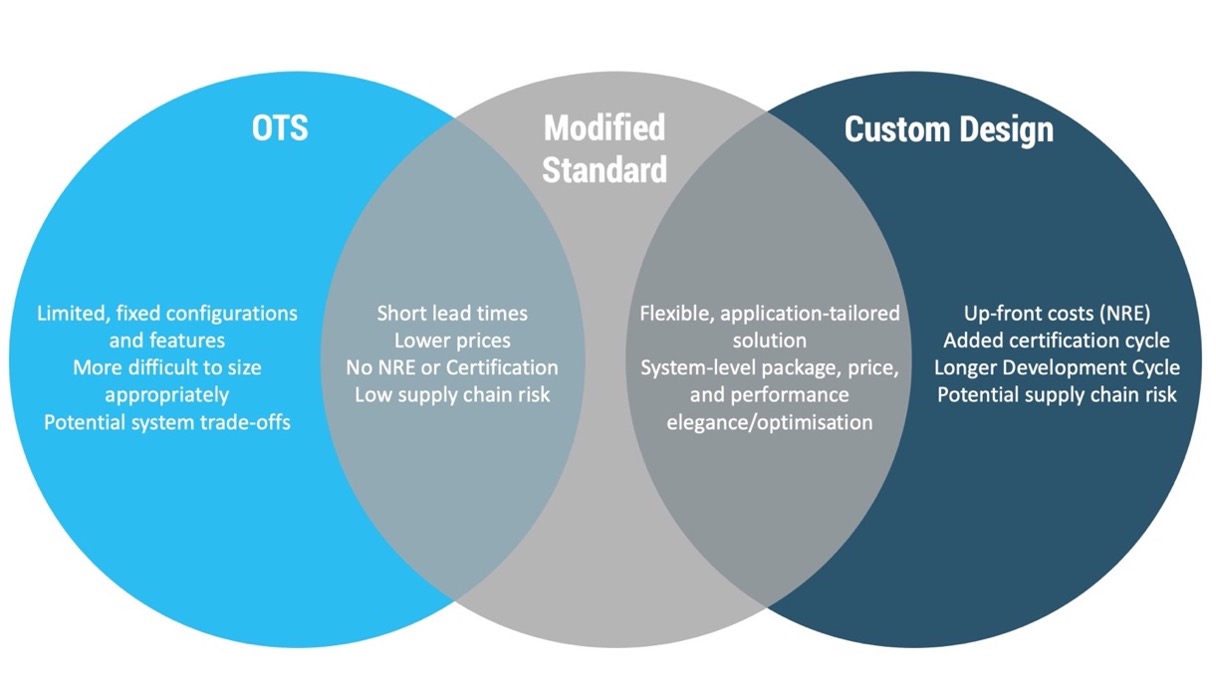

Understanding that it is impossible, or at least impractical to solve every problem for every customer, power supply manufacturers are designing and marketing power converters that solve most problems for most customers. But there is another option. Some power supply manufacturers offer modified standard design solutions, tailoring elements of an off-the-shelf (OTS) converter’s feature set to meet the specific demands of a particular application. This approach allows the system requirements to drive power supply functionality, rather than allowing the power supply to dictate system constraints. Oftentimes, a modified standard power supply is ultimately the most cost-effective and lowest-risk solution.

Figure 1: A venn diagram of OTS & Custom Design with Modified Standards

Types of Modifications An OTS power supply design can undergo a surprising degree of alteration without notably impacting cost or lead time. In fact, modification can result in a more cost-effective solution, and lead time creep is mitigated by working with a true supplier partner.

Modifications do not need to be limited to aesthetic or user interface items like colour, branding, cable, connector selection, etc. It is often possible to adjust parameters of the conversion engine itself such as output voltage set points, protective thresholds (over-temperature, over-voltage, and over-current limits) Electromagnetic Compatibility (EMC) filtering, and even conversion efficiencies at a particular load point.

Adjustment of protection thresholds is a particularly useful design modification that can help greatly reduce total system cost. System designers are frequently tempted to size their power supplies for peak power conditions with added margin. In reality, a power supply can typically be safely sized for the maximum continuous load and can support peak power events through the simple adjustment of an over-current threshold setting. When seeking a power supply with modified protective controls, it is critical to carefully characterise the system and to work closely with the power supply engineers to ensure the full system is still sufficiently protected against fault conditions.

Another common modification is an adjustment of or supplement to the input and output EMC filtering. It is not uncommon for the summation of radio frequency (RF) energy between a power supply and the end device it powers to result in an emissions non-compliance. Once again, off-the-shelf converters have been designed for the general case and attempt to suppress radiated and conducted electromagnetic energy across a broad band of frequencies. The input and output filters can be tuned to target spurious emissions contributed by the product or system. It should be noted that many of the components constituting the input filter are controlled by the power supply’s safety approval listing and cannot always be changed without an agency resubmission.

Advantages Over Custom Power Supplies A modified standard is ready much faster than a custom solution. Proof of concept prototypes can be available within just days. A custom solution will involve lengthy development and product certification cycles that may compromise your target time to market. The engineering effort required to modify an off-the-shelf design is often less than a single week, or sometimes even a single day. A wide variety of common modifications do not compromise the existing regulatory approvals, avoiding the months of agency evaluation and administrative review required for a custom design.

Modified standards incur less sourcing risk than a custom solution. Typically, the bill of materials for a modified standard power supply differs from the standard offering by only one or two line items. Almost all the procurement effort can be shared with the standard offering. Often, production processes and tooling are unaffected by the design modification, meaning your tailored solution can seamlessly run on the same line as the standard offering, on the same day even. A simple Surface Mount Tape (SMT) reel swap or final assembly work instruction swap can be made for the build with minimal effort.

Partner with an Expert The first step to optimising power conversion in your next design is to partner with a power supply expert. The engineering team at TT Electronics can work with you, as an extension of your own engineering team, to identify and deploy the ideal power supply solution. Talk to our team today about a free load characterisation study – a great way to ensure the system drives the power supply requirements, and not the other way around.